No Flay: Improved Clay Brick Cookstove

Introduction

|

MENU |

In rural West Africa over 90% of energy requirements are currently met with wood which is commonly burned using three-stone open fires. This form of combustion is inefficient and requires large amounts of wood. Already 90% of West Africa’s forests have been depleted, with wood being used for fuel as one of the main causes. Furthermore, the three-stone method produces harmful indoor air pollutants, increases the time spent on wood gathering, and emits large amount of green house gasses. The Noflay clay brick stove was designed to address these issues.

|

Local Masons Learning how to construct NoFlay Stoves |

Local Mason making outer bricks |

REAP-Canada and its local partners are currently installing 2500 Noflay stoves in rural communities throughout the Gambia and Senegal. Noflay installation requires a well coordinated series of activities including: community sensitization, mason training, transporting bricks to communities for the construction of a prototype in the village leader’s compound, stove demonstration training, collection of subsequent demand, coordination and transportation of bricks and materials to the community, and monitoring and evaluation to ensure quality control. REAP is continuing to look for more international communities to implement the improved clay brick stove design.

Advantages of the Noflay Stove:

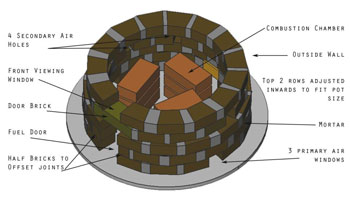

- High efficiency and clean combustion: High combustion temperatures are maintained by restricted and preheated air, secondary air holes allow for further combustion.

- Economical: the cost of production is approximately $8 USD / stove, and is considered to greatly reduce the typical annual cooking cost of $60-200 USD for purchased firewood. Since stoves are produced locally, it provides a possible economic endeavour for the local producers. Fast Boiling: 5 litres of water can boil in 17-20 minutes

- Convenient to use: Requires very little maintenance and internal combustion chamber already resembles the traditional three stone fire

- Lowers Fuel Consumption: Requires less fuel due to more efficient combustion. As well small sticks that typically burn too quick can be used as a reliable fuel source.

- Stove Safety: Protects the home from fire with its outer wall and protects infants from falling or crawling onto the fire. There is no risk of an adult or child knocking over a boiling pot.

- Uses locally available materials: All the materials for the Noflay can be sourced locally which reduces dependence on outside materials or expertise and maintains a focus on local markets.

The Noflay clay brick stove reduces:

Women at a NoFlay cooking demonstration |

- the amount of firewood burned

- household expenditures

- greenhouse gas emissions

- the firewood-collecting burden on women

- household air pollution

- deforestation rates

- Noflay Evolution

- Noflay Training Manual

- Mayon Turbo Stove